Pearlescence, haze, rocker bottoms, and top-load failure are widespread ills that will afflict PET bottles. Cures for all of these can be found.

An article inside the December 2014 problem (Blow Molding Know-How) offered suggestions on the precise option to cope with uneven wall thickness in stretch-blow molding. Whereas that’s an vital problem, it’s hardly the one one which processors ought to deal with on a day-to-day basis. The following are 4 completely different widespread factors, related to every single- and two-stage processes.

1. Pearlescence and haze

These are literally problems with reverse nature that nevertheless could possibly be onerous to distinguish, as every end in a whitening of the bottle.

Pearlescence will also be known as stress-whitening, pointing further clearly to its causes. When PET is overstretched, its microstructure can break up, and the following wall reveals numerous little white circles, due to this fact the connection to “pearls.” Overstretching is a function of every wall thickness and temperature—i.e., a thin wall at a temperature successfully over the glass-transition degree would possibly perform utterly successfully, whereas a thicker nevertheless colder wall would possibly current pearlescence.

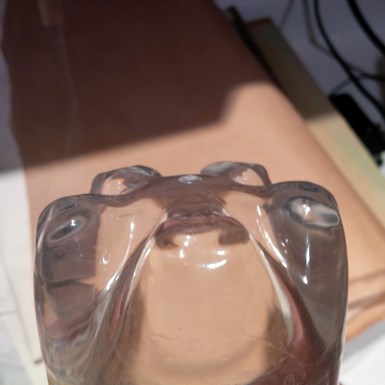

Pearlescence always happens on the inside of the bottle because of the inside of the preform has to stretch rather a lot further. Understanding this makes it less complicated to resolve the difficulty. If the affected area could possibly be very skinny, it must be cooled down and the realm beneath it must be heated to ship further supplies into the whitish part of the bottle. Whether or not it’s pretty thick, the temperature on this half (or basic) must be elevated to allow it stretch further merely.

In two-stage (reheat) blow molding, that’s achieved by altering the lamp or air move settings. In single-stage molding, basic heat is managed by holding and cooling time whereas a change in injection velocity could be utilized to change the temperature inside the preform.

Haze develops when PET in each injection or blow ranges is heated previous about 115°C (240°F) and allowed to sit back down for even a short time. At this temperature, PET molecules have ample freedom to kind crystals, and that is precisely what they might do because of it permits for a lower energy state. In two-stage, the accountable lamp can merely be found and needs to be turned down or air move elevated to keep up the preform temperature underneath 115°C/240°F. Haze always happens on the pores and skin of the preform and air move will cool this half better than the inside. Inside the single-stage course of, cooling and/or keep time are the timers which may be elevated to struggle haze.

Lightweighting has compelled further consideration to topload energy.

2. Insufficient top-load energy

As bottle weights are at all times decreased to keep away from losing on resin use and expense, top-load energy has change right into a far more important problem. Prime-load is often measured on empty bottles in a suitable machine with adjustable velocity. The measured price is then in distinction with the static load (what variety of bottles are on prime of the underside pallet layer) and multiplied with a component of safety (or ignorance) to account for dynamic lots when a truck goes over a bump and your complete load is accelerated up and down. Multiplying static load by two, three, or 4 simply is not a very scientific approach, and some companies have measured the exact load in a transferring truck with sometimes gorgeous outcomes.

Prime-load effectivity depends upon practically solely on wall thickness and bottle design. Bottles collapse on the weakest part of the bottle—be it shoulder, bottom, or physique. Processors ought to know the place the bottle failed to permit them to switch further supplies into this area.

One vexing problem is that top-load values of empty bottles are of curiosity to no one, since empty bottles do not fail as a result of prime loading. Some bottles will current the an identical habits whether or not or not they’re full or empty, nevertheless others will perform as a lot as 4 cases increased once they’re stuffed. Mannequin householders can in any case draw their very personal conclusions, nevertheless processors must have a dialogue about essential prime load with their purchasers if this is so.

3. Insufficient base clearance or rocker bottom

When the underside is simply too scorching after molding, it might shrink outward and sort a center leg that makes the bottle rock, due to this fact the title “rocker bottom.”

All bottles have what’s usually generally known as a push-up: The center of the underside curves inward to quite a few ranges. That’s to make it possible for the bottle sits on the outer rim of the underside or, inside the case of bottles for carbonated drinks, on ft, generally 5. This center push-up will always shrink outward to some extent.

When it is too scorching after molding, it might switch out rather a lot that it begins to protrude previous the boundaries of the outer rim, and the bottle “rocks” as an alternative of standing straight. It’d moreover happen that residual air stress contained within the bottle pushes the center of the underside out when the mould opens, even though this could be a considerably unusual prevalence. On some machines, cooling jets blow air on the bottoms of the bottles after molding to forestall that shrinking-out. In another case, the processor has to reduce heat on the underside of the preform or enhance cooling time.

An excellent indicator of pearlescence is its prevalence in extraordinarily stretched areas identical to the ft on this 15 L container.

Base clearance—the hole of the center of the bottle bottom to the ft—is of utmost significance for carbonated drinks. It’s as a result of the carbonation inside the product can exert stress of as a lot as 70 psi contained within the bottle. This stress then pushes on the center disk of the bottle base, which as a result of this truth has to have some room to maneuver sooner than it exceeds the depth of the ft. Base clearance must be measured in short intervals, generally 2 hr. It is normally the one parameter that retains machines from working sooner because of the necessary cooling time.

Insufficient orientation in skinny spots is further widespread in single-stage than two-stage molding.

4. Drop-impact failure

Bottles ought to resist being dropped from 4 to 5 ft containing water at spherical 4°C (40°F) to simulate circumstances in a household fridge. Reverse to polyolefins, PET does not break on the thinnest nook (till there could also be pearlescence or haze); it may dent nevertheless will not break because of it is extraordinarily oriented in these skinny spots. A shortage of orientation is because of this truth the most common clarification for failure, most continuously current in custom-made bottles with small stretch ratios and additional widespread in single-stage than in two-stage molding.

In two-stage molding, a cooler preform temperature will stress further orientation into the material and improve effectivity. In single-stage processes, cooling or keep time needs to be added, which might enhance cycle time. Preserve time has further impression because of the preform shrinks away from the core all through the cooling half and is because of this truth hottest. When preforms are overheated to the aim of haze, the crystalline areas are further brittle and in addition can fail. The an identical remedy applies.

ABOUT THE AUTHOR

Ottmar Brandau has been working inside the plastics commerce since 1978 and is the president of PET All Manufacturing Inc. His e-book, The Speedy Info to Good PET Bottles, describes 30 widespread points and their choices. It could be found at blowmolding.org/retailer. Contact: (705) 429-1492; information@blowmolding.org.