The plastics commerce has acknowledged that it has to produce additional sustainably whether or not it’s to satisfy the needs of end clients’ altering consumption habits and ever stricter environmental legal guidelines worldwide. Recycling performs a key perform in reaching this goal. Many plastics processing operations are coping with the question of how one can implement recycling on an industrial scale on the best prime quality.

At this degree, new hopes akin to biodegradable plastics cannot meet the extreme expectations positioned upon them. The plastic merchandise will solely degrade beneath very explicit conditions. Educating consumers on right disposal is continuous sluggishly, and the waste commerce is struggling to appropriately exploit this new supplies stream. Notably regarding packaging, normal plastics akin to PET, PE, or PVC will stick with out opponents for the foreseeable future. As a option to consistently reduce outcomes upon the setting caused by the use of plastics, the plastics commerce has no choice nevertheless to turn into spherical.

As a option to improve the proportion of secondary raw supplies for processing as quite a bit as potential, it is preferable from the angle of the recycling agency that waste plastic be as easy to course of as new supplies.

For any of these recycling strategies, mechanical instruments design ought to adapt to satisfy the altering requirements to cope with delicate (low bulk density) and heavy (extreme bulk density) provides to verify right dosing. This article is going to sort out the evolution of recycling and what a processor ought to consider when evaluating his current feeding instruments and the feeder’s potential to watch, sample and react to course of variations. The provision of this data, and its administration in accordance with Enterprise 4.0 automation, can allow the end-user to adapt to future manufacturing requirements which can embody higher traceability, flexibility, adaptability and basic effectiveness.

As a option to consistently reduce outcomes upon the setting caused by the use of plastics, the plastics commerce has no choice nevertheless to turn into spherical.

Challenges of Feeding Provides into the Course of

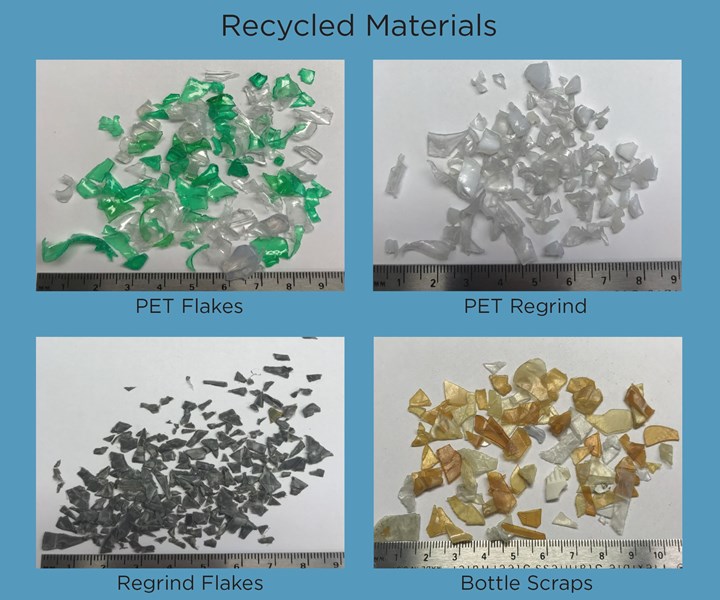

One notable distinction between essential and secondary provides is especially vital all through feeding. Like just about any recycling supplies, waste plastics are heterogeneous in measurement, kind and bulk density. Subsequently, the appropriate number of feeding experience is crucial to creating certain optimum bulk supplies flow into.

Most likely probably the most relevant feeding experience for the equipment have to be every technically applicable and economically atmosphere pleasant with regards to funding and operation. It is helpful to rely upon suppliers which have mastered quite a few utilized sciences and should thus provide the acceptable feeding system for any case. Some distributors provide, as an example, weigh-belt, vibratory and screw feeders, together with others. Each experience has its private advantages—what’s decisive is the strategy know-how that brings operational requirements and processes collectively.

Single-screw extruders, ubiquitous in plastics recycling, are operated primarily using volumetric feeders, which can be suited only for feeding bulk provides with fixed density. When coping with secondary raw provides, the bulk supplies traits described above can shortly end in irregularities in flow into habits.

In distinction, twin-screw extruders—usually used to upcycle secondary plastics to a larger prime quality—are usually operated with gravimetric feeders, which perform rather more precisely and, as a result of burden signal, can react increased to fluctuations in bulk density and supplies flow into (Fig 1). Moreover, their feeding effectivity is precisely documented.

Coping with Troublesome-to-Flow into Provides

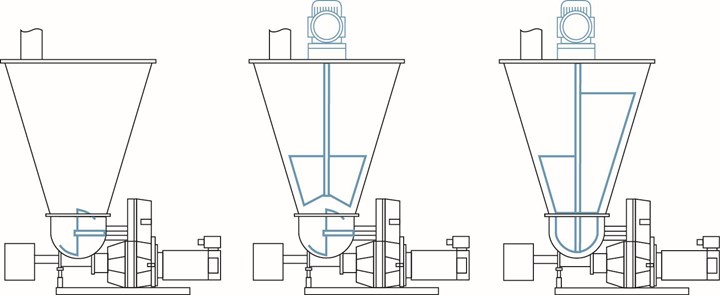

In some circumstances, feeding recyclates presents challenges to feeding-equipment suppliers. Earlier to selecting the proper feeder, you will have to make sure that the material will probably be able to make it by the hopper to the feeding gadget. On account of variations in supplies sizes (Fig. 2), bridging (arching) or rat-holing may occur. Strands of recyclates that mesh collectively are inclined to kind a bridge above the screw extraction gadget that will find yourself within the feeder ravenous for supplies. The tip finish outcome could be catastrophic to the integrity of the product recipe and finish in off-spec product being generated. To struggle this draw back, distributors resort to exterior agitation (Fig. 3).

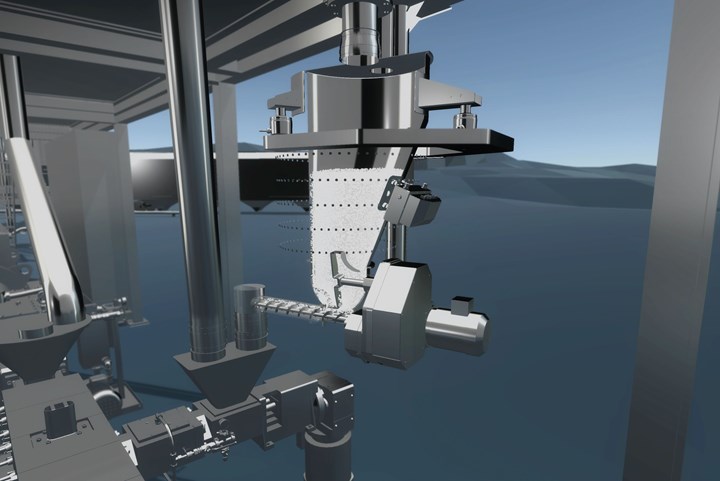

Throughout the case of loss-in-weight (LIW) feeders, exterior vibration, along with utilizing customary vibrators on feeder hoppers, may trigger interference with the LIW signal if the administration system cannot filter out this vibration. Alternatively, there are some new administration utilized sciences obtainable that benefit from vibration utilized to the hopper, such as a result of the Coperion Okay-Tron ActiFlow bulk-solid activator (Fig. 4) that embody an exterior drive tied immediately into the burden system controls. This drive operates at a variable frequency and amplitude based totally upon the weighing and administration system detecting non-uniform supplies flow into by weight.

FIG 3 Quite a few agitation strategies are utilized by feeder suppliers to forestall bridging, which can be catastrophic to the integrity of the product recipe and finish in off-spec product being generated

This real-time gadget prompts the outside vibration solely when there could also be an upset inside the LIW signal, akin to inside the case of rat holes or supplies bridges. Such a “wise” vibration gadget will also be self-tuning, with the controller adjusting the frequency and amplitude to compensate for changes inside the hopper fill diploma or supplies flow into, thus stopping bridges or rat holes sooner than they are going to kind.

Feeding Experience

As comparatively straightforward components, weigh-belt feeders are reliable, gravimetric feeders that present extreme precision and atmosphere pleasant course of administration. They may reliably feed large volumes of bulk supplies and provides with varied flow into properties, since they weigh the bulk supplies earlier to discharge and actively adapt belt velocity. Weigh-belt feeders are suited, as an example, for processing recyclates with fluctuating bulk density.

In plenty of functions the weigh-belt feeder is blended with a screw feeder as a pre-feeding system as a option to clear out the mass flow into or to reliably transport provides which can be inclined to kind bridges onto the belt. One extra profit is that, relying upon the state of affairs, weigh-belt feeders, even with pre-feeders, usually require a lot much less vertical clearance than totally different fixtures. Many weigh-belt feeders will be discovered with optionally accessible heat-resistant silicone belts for functions the place the bulk supplies is coming from a heated course of upstream.

If smaller recyclates or flakes are being fed, or if glass fiber is added into compounding processes, vibratory feeders could be a viable varied. These feeders will be present in quite a few sizes with a set of tray configurations to pick out from, relevant for the equipment in question and for conveying a wide range of bulk provides. The absence of mechanical parts that are matter to placed on is advantageous for regular operation; vibratory feeders are just about maintenance-free consequently. The bulk supplies experiences no mechanical impression, each. The necessary factor to worthwhile implementation is to verify the material will flow into from the extension hopper above the vibratory feeding module with out an arch or bridge being formed.

If smaller recyclates or flakes are being fed, or if glass fiber is added into compounding processes, vibratory feeders could be a viable varied.

Nonetheless, significantly for firms who’re dedicated to using a very powerful recyclate parts potential, these feeding utilized sciences are insufficient. If the material presents very irregular sizes or sorts, beneath certain circumstances a screw feeder have for use—normally with a single screw. The feeder’s rotating screw conveys and feeds the material from a hopper into the strategy underneath. Using the screw and the horizontal agitator, uniform mass flow into is ensured. Screw feeders will be present in quite a few sizes and configurations.

One ought to differentiate between single- and twin-screw feeding. Every sorts will be present in gravimetric and volumetric designs. Twin-screw feeders significantly are moreover utilized at a later time restrict alongside the value chain—for occasion, in compounding. Proper right here, the experience distinguishes itself by the precise feeding of finer bulk provides, which is primarily applicable for parts. Due to the extreme precision of the corresponding weighing experience and precise administration algorithms, additional provides are fed precisely into the strategy based mostly on the recipe, and the end-product prime quality is constantly optimized.

The Feeder Controller

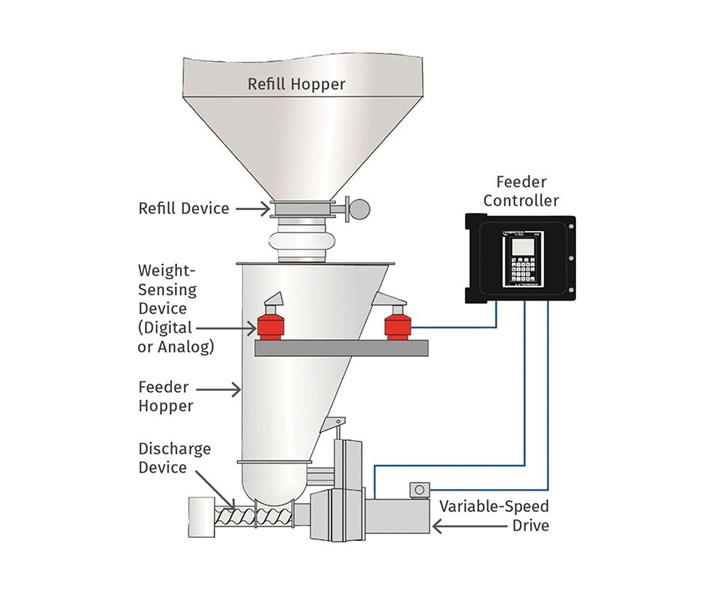

In case your feeder supplier was worthwhile in recommending an accurate feeding decision, we’re capable of now understand the system’s efficiency. Sooner than discussing the experience enhancements and information that could be derived from the feeder, you will have to understand the important concepts of operation. The LIW feeder consists of a feed hopper, refill gadget, discharge gadget with a variable-speed drive, weight-sensing gadget (each digital or analog), and controller. A feeder operator items the material feed worth (setpoint) by sending information to the feeder’s controller (Fig. 5).

FIG 5 The LIW feeder consists of a feed hopper, refill gadget, discharge gadget with a variable-speed drive, weight-sensing gadget (digital or analog) and controller. A feeder operator items the material feed worth (setpoint) by sending information to the feeder’s controller.

When the feeder is in operation, the discharge gadget attracts supplies from the feed hopper and meters it to the downstream course of. The load-sensing gadget consistently research the material weight inside the hopper (internet weight) to the controller. The controller calculates an exact feed worth based totally on the loss in internet weight, compares it with the setpoint, and can improve or decreases the discharge gadget’s drive velocity to hurry up or gradual the net-weight change (the dearth of supplies inside the hopper) so the feed worth matches the setpoint.

To forestall feeding interruptions, the controller periodically directions the refill gadget to refill the feed hopper with supplies. All through each transient refill cycle, the net-weight signal from the hopper is rising, so it might’t be used as a administration signal to learn the way quite a bit supplies is being delivered to the strategy. To compensate for this, the LIW feeder briefly operates in volumetric mode all through refill.

The feeder controller could be built-in proper right into a supervisory process-control system that shows the entire feeders and totally different instruments in your course of. The subsequent information explains how information collected by the LIW feeder may show you how to catch course of points early, assure product prime quality, and catch setup errors sooner than startup.

Improve Productiveness by Trending Feeder Effectivity

The LIW feeder’s potential to assemble course of information in precise time may show you how to catch small course of points sooner than they turn into large ones. At current’s superior controllers can embody communication via every kind of protocols, with some even along with built-in Ethernet and optionally accessible Wi-Fi modules. Newer controllers can retailer historic information knowledge for an extended timeframe. This data can embody the feed worth, internet weight, and drive-speed-to-feed worth relationship (known as the feed difficulty). Some distributors might even current as a lot as six months of information storage inside their customary manufacturing unit supplier system.

In regards to the Creator: John Winski is dir. of product sales for Coperion Okay-Tron, Sewell, N.J., the place he is chargeable for product sales inside the Americas of feeders, pneumatic conveying and engineered strategies. He has 32 years of experience at Coperion Okay-Tron and has held positions as a service engineer, enterprise engineer and regional product sales administration. Contact: (856) 589-0500 jwinski@coperionktron.com; coperion.com.